© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

The preparation of the warp consists in transferring the yarn, packaged in reels, spinning tubes

or cones, on the beam to be placed behind the loom and ready for weaving.

There are three types of warping used in production:

1) The warping in sections or capacities - used for limited lengths and in particular for patterned fabrics,

both by color, by title, by twist.

2) The fractional warping - used for high production of gray fabrics and fabrics with simple effects

of drawing, like striped with few colored threads compared to the total of threads.

3) Vertical warping - used for very limited runs, less than 100 meters, intended for manufacturing

of samples, standard pieces, handkerchiefs and specimens.

The type of warping that characterizes the production of our textile district is that of sections or capacities

while for sampling it is the vertical one.

For this reason a more detailed description of the sectional framework will be made.

With this, groups of wires called capacities or sections are wound on a large cylinder called a barrel,

one after the other, until all the warp threads are wound in the required length and height

for the warping. Once all the established capacities have been wound, the warp is transferred onto the beam

intended for the frame.

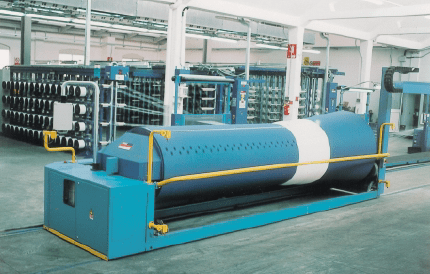

The warper is basically made up of:

• a creel, a special rack where the spindles or cones that will form the threads of each are arranged

scope;

• two combs, the first for winding and the second for reduction;

• a barrel.

The winding comb keeps the even strands separate from the odd strands to give each of them their own

position to always be maintained even during weaving: only one thread passes through each tooth.

The reduction comb gives the flow rate the right height which, repeated many times, constitutes the height

of all the warp threads: obviously more threads pass through each tooth.

The barrel consists of a large cylinder having a conical shape in the initial part, which prevents

to the threads of the first flow to overturn with the increase of the thickness of the flow itself (meters

warps). The same process is repeated for each course, and one rests on top of the other.

An electronic control panel helps the operator to program all the technical parameters

indispensable for the regular carrying out of the warping process. Once the winding is done

of all the warp threads, these are simultaneously unloaded from the barrel and poured onto the

beam intended for the frame (unloading of the barrel). In this last phase the passage is sometimes foreseen

of the threads, before winding them on the beam, in a tray containing auxiliary products for

improve the smoothing or reinforcement of the threads, depending on the type of warp yarn.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me