© 2024 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

We are happy to assist you

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

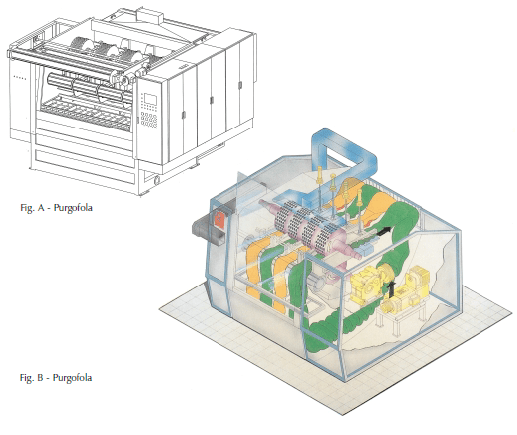

This process has the purpose of fulling and washing in rope, in a single machine - called purgofola -

several pieces (from 4 to 8), inserted on 2 or 4 fulling groups. The basic concepts of the two processes are the same

dealt with in the sheets of the two processes (see: fulling and washing).

The whole purge machine (see figures A and B) is made of stainless steel and is automated

to ensure greater productivity, increasing cost-effectiveness and cleanliness of processes.

To treat fabrics in a different way that require different fulling percentages for each case

fulling has independent controls, with an automated management of the whole process.

By excluding the pressure of the power strip, only the purge operation is obtained.

The program overview allows constant control and optimal treatment of the pieces being processed.

The person in charge of processing must adopt a behavior similar to that indicated for both the process

for fulling and for rope washing.

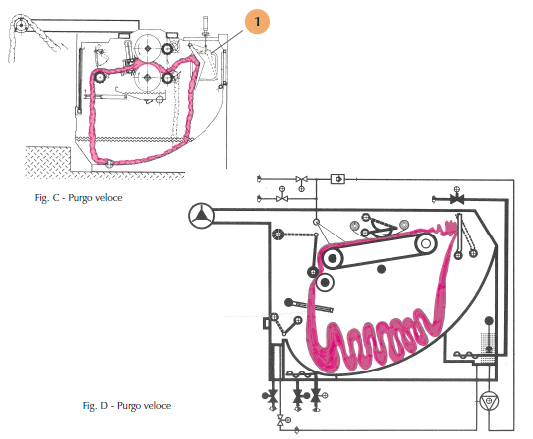

The quick purge (see Figures C and D) is a wash similar to the rope wash but performed

with measures that increase the working speed and avoid the formation of dead folds.

It is suitable for both carded and combed fabrics.

To achieve even a slight feathering and a fuller hand of the fabric, this process involves

the flapping of the pieces on a special plate placed inside the rear wall

of the tank (see figure C, point 1).

The elements that differentiate this process from a normal rope wash are:

the speed of work;

the metal plate for shaking the pieces;

the different systems of dragging the piece, such as conveyor belts instead of cylinders

squeezers, for the treatment of different types and qualities of fabrics.

Washing and desizing, which have the purpose of removing all impurities from the fabric (sizes,

textile oils or dirt, also resulting from previous processing), can be performed in

three ways:

to. rope washing (for heavy fabrics, mainly carded);

b. wide washing (for light, delicate, combed fabrics, etc.);

c. continuous washing (wide for large productions).

However, the washing process consists of four successive phases:

1. Soaking

The fabric is impregnated with water and a mechanical rubbing action eliminates the substances

insoluble substances, such as earth, powder and unfixed dyes, etc.

2. Pre-wash

Cold wash, light and fast, which eliminates excesses of color and dirt, which could

fix on the piece in the subsequent degreasing phase.

3. Degreasing

A water bath containing soaps, detergents and auxiliary products, in which the

oily substances used in spinning and any sizes, oily stains, etc.

The temperature of the bath is fundamental, which varies in relation to impurities and components to be eliminated

(from 20 ° C to 60 ° C).

4. Rinsing

With an abundance of water, the emulsion with all the substances to be removed is removed.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2024 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me