© 2024 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

Stricatura works on fibers previously raised with the raising process and gives them

a wavy and definitive look. It is carried out on pieces previously soaked with water, using

vegetable thistles, preferably already used, so that they have less raising strength but

still elastic tips.

The machines that carry out this process can be of two types.

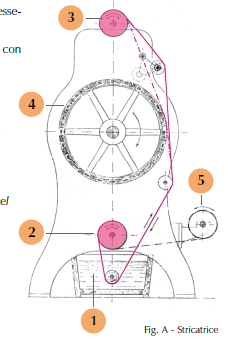

The simplest type involves only one contact of the fabric with

the thistles (see figure A). The fabric, constantly wet, passing into the tray below (fig. A, point 1), is alternately wound on two rollers placed one below (fig. A, 2) and the other above (fig. A, 3)

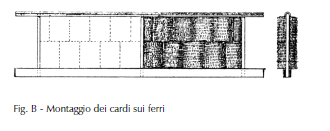

the drum (fig. A, 4) which carries the “irons” (fig. B). Each iron is made up of a rectangular telarino in which the vegetable thistles are stably wedged. The action of the drum is always in the same direction,

because its speed is much higher than that of the fabric.

At the end of the treatment, the fabric is wound on a roller outside the machine (fig. A, 5).

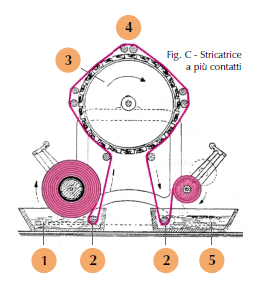

The other machine (fig. C), more productive than the previous one, foresees several points of contact of the fabric on the thistles placed in any case on a single drum. The fabric to be subjected to this process passes into a tank (fig. C, 1), where it is soaked in water at room temperature or, in some cases, at 50 ° C in which auxiliary products can be dissolved; between the tensioning cylinders (fig. C, 2), it slides on the drum (fig. C, 3) where the contacts with the thistles occur.

Four pairs of cylinders (fig. C, 4), placed above the drum, approaching it,

they increase the contact area between thistles and fabric while when they move away this area decreases until it disappears.

The wrinkled piece then passes into a tray (fig. C, 5), still impregnating itself with water; it is then rolled up and remains in this state for a period of 24 hours, always in motion, to obtain a better fixation and shine of the hair.

The analogies of the machine and of the principles with the vegetable gauze are evident; for this reason the behavior

of the operator is very similar to that adopted for the vegetable raising to which

please refer.

The only substantial difference is that in vegetable gauze there is a rotary movement of both the drum

that of the thistles arranged obliquely, while in the stricatrice there is a rotational movement of the

drum with thistles that are horizontal and fixed.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2024 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me