© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

The application on fabrics of dyes or finishing products with continuous procedures

usually takes place with devices called foulards, therefore the operation is called foularding.

The fabric first passes through expanding and tensioning cylinders and then, wide, into a tray in which

is impregnated with the solution or suspensions of the substance to be applied (for example dyes,

optical brighteners, pre-condensed resins, pigments, softeners, etc.).

Squeezing between cylinders follows, both to push the liquid into the fibers and to eliminate excess.

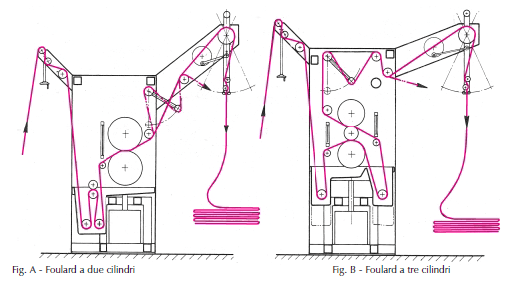

There are two-cylinder padding machines (see figure A) but the types of padding a are also frequent

three superimposed cylinders (see figure B), which involve two impregnations and two squeezing.

The quality of the workmanship is influenced by the type of material that covers the cylinders, which can be

stainless steel, brass, rubber with different degrees of hardness, ebonite, etc. or balanced combinations of

these materials.

The choice of using two or three roll padders depends on:

the ability of the fabric to absorb water (hydrophilic = high absorption);

the speed you want for the treatment.

a) Normally, for a hydrophilic fabric that "foulards" at low speed, the two cylinders are used.

b) With a little absorbent fabric, or if you want to adopt a high speed, the three-cylinder is better,

remembering that in this case you need a tray with a greater volume of liquid.

Remember that:

a good impregnation of the fabric is essential for all padding procedures;

the amount of retained bath is always proportional to the weight of the fabric;

a rapid and uniform impregnation is obtained with an adequate pre-treatment that makes the

more absorbent fabric;

less fluidity of the padding liquid can cause less residual impregnation;

the degree of squeezing to be exerted on it is important for subsequent processing.

Examples:

in the presence of intense colors, an effect with a high watery residue on the fabric is sometimes required,

this allows lower concentrations of dye and avoids reaching the solubility limits of the

same;

if the padding is followed by drying, an effect with less water residue is preferable,

which also allows energy savings in that subsequent phase;

if the wet fabric passes to a second impregnation, for example of reactants, carried out

still with a foulard, a low aqueous residue is required.

In any case, a reduced residual of water on the fabric:

a) reduces the dangers of migration of dyes during drying;

b) allows easier corrections of the composition of the impregnating bath,

made necessary for example by preferential absorptions of the dye.

The high or low aqueous residue effect after squeezing also depends on the passage speed

of the fabric in the process and from the cylinders, in particular:

by the pressure exerted by the cylinders;

from the materials with which the cylinders are made, which determine their hardness;

the size or diameter of the cylinders, which determines the size of the squeezing area.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me