© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

We are happy to assist you

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

The drum, whose treatments are based on the same principle as domestic washing machines, is used:

in the finishing of fabrics for normal washing of ready-made garments or small batches of fabric;

to obtain light felting of wool or mixed wool and a feathered surface;

for the finishing of knitted fabrics made with fine fibers (cashmere, angora, alpaca, etc.);

to give a soft and slightly velvety hand to a cotton fabric.

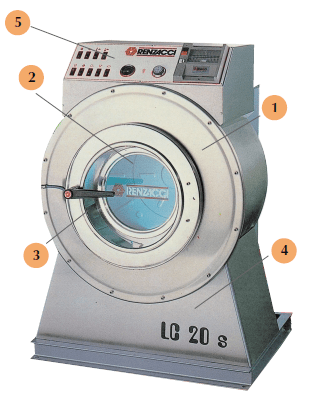

The appliance consists of:

a containment barrel

(see figure A, point 1) within which it rotates; a drum or basket (fig. A, 2)

equipped with 3 or 4 flaps for the flapping of the fabric and holes, which allow the circulation and extraction of the bath;

a large porthole (fig. A, 3),

with automatic closing, for the introduction

of the fabric;

a fairing (fig. A, 4) which contains both the barrel and the drum;

the integral automated control panel (fig. A, 5) with variable card programmer for

adjust washing times, temperature,

liters of water needed, etc .;

a push-button panel for operations from

carry out manually.

In the rear part of the appliance there are two inputs for the introduction of hot and cold water and another for the introduction of steam, a drain and a motor equipped with variable speed inverter for partial or slower reversals of the rotation of the drum.

The basket treatment processing program includes: a) pre-washing; b) discharge; c) the short spin; d) filling the barrel with water added with auxiliary substances;

e) washing; f) rinsing; g) the total spin. The different treatments are obtained by varying the times, temperature and quantity of the bath in these phases.

The bath ratio is 1 to 10 for normal washing, while for special treatments this ratio

rises to 1 to 20.

At the end of the processing in the basket, the centrifuged fabrics, still damp, are treated in a drying machine

basket inside which hot air circulates.

The operator must:

weigh the tissue and consider the desired results to define the best treatment;

set and check the parameters established for the treatment on the control panel;

in particular cases, its manual intervention on the push-button panel may be required;

make sure that the automatic closing of the door has been carried out regularly, if not

the car does not start. Conversely, the door lid does not open if the machine is not

stop.

Any defects are due to an incorrect setting of the treatment program.

Altered appearance and hand of the fabric, caused by too high temperature.

Dimensional variations of packaged garments and other results that do not correspond to the sample, may

depend on an incorrect evaluation of the timing of the various process phases.

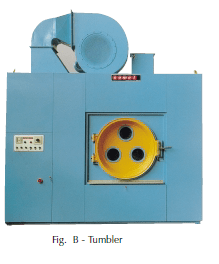

By means of the tumbler basket treatment, (see figure B)

with rotations in both directions and jets of hot air and steam on the

fabric, this or the sweater with fur create a perfect

imitation of the lamb fleece. At the end of the work the

fabric is cooled.

Regarding, in particular knitted fabrics, the treatment

in tumbler basket:

dries perfectly, eliminating wrinkles and lo

crushing of the bells due to the operation

of tincture;

by steaming and beating the trimmed fabric in hot air

it ennobles it, making the bells swell and parallelize

that acquire brilliance.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me