© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

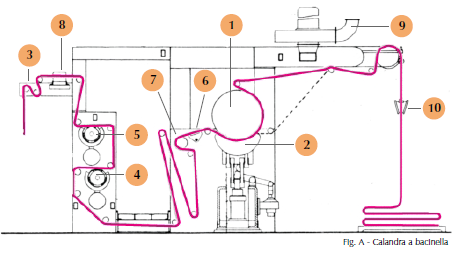

The calendering gives the fabric an ironed, flatter and shiny appearance. It is performed by subjecting

the patch to a strong compression between two heated surfaces.

The calendering unit is composed of a large rough cylinder (see figure A, point 1) and a hollow and mobile tray (fig. A, 2), covered with a stainless steel or brass sheet. The fabric flows between the smooth plate of the basin and the cylinder which, by rotating, drags the piece. The fabric is pressed

to the cylinder from the bowl with adjustable pressure. Steam circulates inside the cylinder and basin,

which can reach and maintain a uniform temperature of 120-130 ° C, with relative discharge of

condensation. The piece passes in succession through: a tension piece (fig. A, 3), which regulates the incoming tension;

a metal detector (fig. A, 8), which stops the machine if it detects a ferrous body in the fabric (darning needle, needle, etc.), to avoid damage to the calendering unit;

two rotating brushes, one on the right side (fig. A, 4) and the other on the reverse side (fig. A, 5), which eliminate residual dirt from the fabric that a suction system then conveys into suitable containers;

a stainless steel plate or cylinder with a herringbone surface, which holds the stretched fabric;

a steaming tank (fig. A, 6), which allows a slight retraction in height and gives stability

to ironing;

a boost cylinder (fig. A, 7), which, if used as such, allows to contain

to the minimum the tension of the fabric in the sense of the warp, decreasing its elongation;

the calendering unit and then in

a cooling and conditioning area (fig. A, 9) or more simply a cylinder

swivel perforated with forced air suction, cools the fabric;

a folding machine (fig. A, 10) or a roller.

In the passage of the fabric between the cylinder and the basin, the right side of the fabric is in contact with the cylinder.

When you want to get a shiny right, especially on pile fabrics, the right comes

placed in contact with the basin because in this way a greater shine is obtained.

For tubular knitted fabric, before entering the machine, it is necessary to make it widen

the piece by means of a device consisting of two expanding units (see figure B, point 1) e

by a series of two felt-covered wheels (fig. B, 2) for each expanding unit they serve

for advancing the fabric. A manual device to set the height of the mesh

(fig. B, 3) by moving the blocks, it allows the fabric to be introduced into the calender well

lying down.

At the beginning of the morning shift, the operator must:

switch on the control panel;

heat the calendering unit, opening the steam inlet to the rotating cylinder and to the

bowl lowered (i.e. detached from the cylinder);

bring the pieces to be calendared at the entrance of the machine and sew the tail (with the right

facing the basin -low- if you want a glossy effect on the right side) to the drawing-in cloth.

As soon as the group has reached the working temperature, the operator must:

calibrate the degree of brushing;

check the efficiency of the metal detector;

operate the steam tank with the desired steam;

when the end of the piece reaches the cylinder, adjust the pressure according to the type of fabric;

adjust the calendering speed;

if required, activate the cooling by means of the outlet cylinder;

detach the drawing-in sheet;

finally, adjust the end of the piece on the pallet with the packer already in operation.

These operations are carried out every time the article is changed to work.

At the end of the evening work shift, it is necessary to turn off the steam, put on the drawing-in cloth, lower

the cuspidor, switch off the control panel.

Presence of creases, if the fabric enters overdue due to bad spreading.

Diversity of crushing between center and selvedge, due to the linearity of the bowl not well adjusted.

Areas with small and dense wrinkles, due to soap or grease residues on the bad patches

wash.

In addition to keeping the work environment and machine clean, the operator must check frequently

the progress of processing, in particular:

check at the entrance to the calendering unit that the wefts are in straight edge, in the machines

without weft straightener. The right thread is clearly visible on the patterned fabrics, in the plain ones the operator

must ensure that the seam between one piece and the next passes in the right thread, with any small ones

corrections by hand;

keep the selvedges under control which, if too loose, can create side folds.

In this case, increase the tension on the tensioner and do not use the supercharger;

be ready to stop the machine, in case of patches that "attach" due to bad purging or due to

other causes.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me