© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

The polishing gives brilliance and shine to pile fabrics of wool, wool blend and fine fibers.

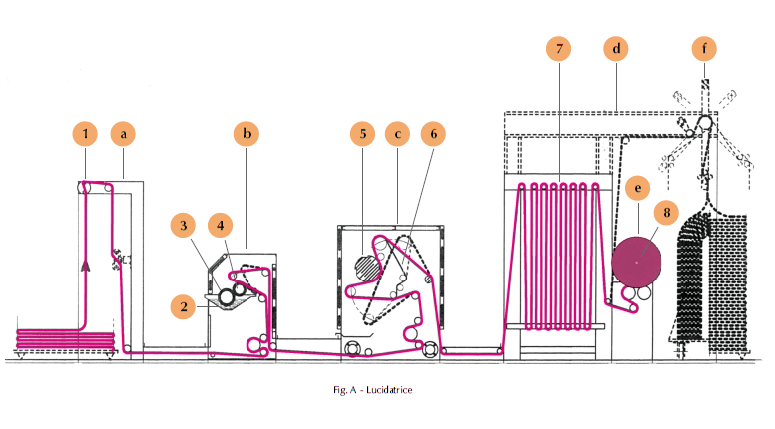

The machine in its main parts consists of:

a first block for inserting the piece (see figure A, point a);

a dresser unit (fig. A, b), which applies a solution of water and chemicals to the pile of the fabric;

a polishing and drying unit (fig. A, c);

an accumulator of the treated tissue (fig. A, d);

a rolling unit (fig. A, e) and, optionally, a folding unit (fig. A, f).

The patch passes through:

two tensioners (fig. A, point 1),

the accompanying cylinders of the dresser unit, where the solution of water and chemical products present in the tray (fig. A, 2) is deposited on the pile of the fabric by means of the cylinders

(fig. A, 3 and 4) and, in particular, when passing over the upper cylinder (fig. A, 4).

The piece comes into contact with the polishing cylinder (fig. A, 5) - in steel heated by electric resistances and equipped with special combs on the four grooves - which moves at a variable number of revolutions, is connected to an inverter which confers a

reciprocating motion and performs the drying, polishing and ironing of the fibers.

A felt sleeve (fig. A, 6), adhering to the adjustable polishing cylinder, finally allows to obtain an oriented pile.

A fabric accumulator (fig. A, 7) allows you to change the roll of fabric already treated (fig. A, 8) without stopping the machine.

The operator must:

sew the pieces to the drawing-in cloth;

put the bath in the tub;

adjust the pressure of the felt sleeve and the processing speed according to the type of fabric;

start the treatment, removing the drawing-in sheet as soon as it reaches the end of the work.

In relation to the hairy surface to be treated and the amount of desired glossy effect, act on the path of the dresser group, excluding or not the passage from the relative cylinder, adjust the passage on the polishing group, using the felt sleeve.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me