© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

Unlike the classic fabric, consisting of two elements (warp and weft) that are intertwined with each other

them, in the knitted fabric there is only one element that works on itself, that is, imagining each

rank with the previous and with the next.

Knitted fabrics can be in weft or in chain.

We define a knitted fabric in weft that structure consisting of a single element, the weft, arranged

horizontally with curvilinear evolution. The creation of the weave takes place for

by means of needles, with the formation of the stitches one after the other in horizontal succession and with the union

of them. The resulting fabric is extremely stretchable in both directions.

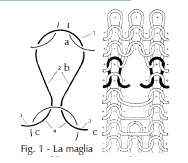

The constituent element of these fabrics is the knit which is made up of three fundamental parts

(see figure 1):

1. needle head or bushing (fig. 1, point a);

2. rods (fig. 1, b);

3. platen bushings (fig. 1, c), which when joined together form

the interlink.

The horizontal succession of meshes is defined rank. Yup

row defines the vertical succession of meshes that correspond

to the work of a single needle.

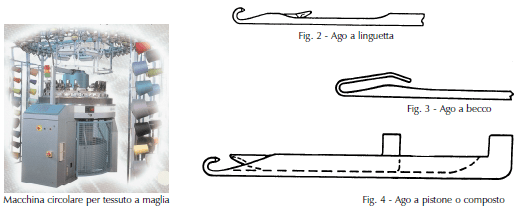

The needles used for the manufacture of knitted fabrics are of three types:

1. tab needle or automatic needle (see fig. 2);

2. beak needle also called elastic needle (see fig. 3);

3. compound needle or piston needle (see fig. 4).

The first distinction that needs to be made is that between looms and machines. In the looms the needles, which can

be both beak and tongue, they are all mounted on a bar that can be fixed or mobile, but

in both cases the needles all perform the same work simultaneously. In the machines, however,

the needles, which are only of the automatic type (tab), are mounted on the needle beds in special

grooves and are moved individually; then the various needles carry out the knitting cycle in

sequence one after the other. Both the machines and the looms can be built both in rectilinear form

than circular. Finally, they can be single-knit (with only one set of needles) or double-knit

(with two sets of opposing needles).

Classification of weft knitted fabrics

The main types of weft knitted fabrics are:

1. basic fabrics, when the machine does not require any selective control of the needles;

2. derived fabrics, when the control of the needles with a limited variety is sufficient;

3. operated fabrics, when each needle is controlled individually and therefore a design is possible

wide field for weaving and for color;

4. composite fabrics, when additional elements are added such as, for example, sponge,

plush, plated.

The drawing effects that can be achieved on each of these four classes are:

to. weaving effect (variation of the knitting method);

b. color effect (creation of designs, using different colors and types of mesh);

c. padding effect (obtained by inserting additional threads and wefts).

The basic classification of weaves that can be produced on looms or rectilinear machines or

circular, is as follows:

to. plain jersey fabrics (single jersey), obtained with a series of needles;

b. rib knit fabrics (double jersey), obtained with two sets of crossing needles and,

therefore, staggered with each other;

c. cross-knit fabrics (interlock), obtained with two series of facing needles but which

they work with alternating needles;

d. reverse knitted fabrics (links - links), obtained with a single series of double hooked needles that

they work on two needle beds.

In chain-knitted fabric a series of warp threads form the stitches simultaneously.

The difference between the weft mesh and the chain link consists in the fact that in the chain link,

since each needle is fed by its own thread, the interlink is not arranged horizontally

but it is placed vertically or diagonally forming a bridle.

The primary weave obtained by making each needle work with its own thread is called a chain;

of course in this case you don't get a fabric but a fringe. To transform that

fabric fringe it is necessary to tie the chains together with a variable movement from a needle

to the other.

The looms for chain knitting have a very high production capacity and have a high

versatility being able to produce elastic fabrics such as those knitted in weft, compact or perforated

like tulle or nets, smooth or textured.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me