© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

Process suitable for delicate or knitted fabrics in natural or synthetic fibers (polyester excluded).

The fabric, sewn in rope, is transported by spontaneous fall together with the bathroom current,

with a very low bath ratio.

This dyeing system, which can take place under light pressure, reaching 108 ° C, replaces

the old reel system in an open tank, since it allows a considerable saving of water and, in

some cases, even of coloring materials (for example in dyeing with direct dyes).

Special overflow under pressure - for dyeing delicate articles or fabrics in 100% polyester

or mixed with other cellulosic, synthetic fibers, etc. - they reach 130 ° C.

The devices have 1 to 6 channels. The described path is related to a single channel.

The piece:

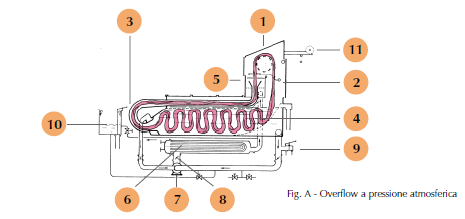

it is put into the machine by an auxiliary circular reel controlled at variable speed (A, point 1);

passes through a piece guide comb (fig. A, 2) with a safety stop device through

a funnel (fig. A, 5)

is dragged together with the bath through a U-shaped tube (fig. A, 3),

reaches the relaxation chamber (fig. A, 4) where it floats in the bath without any tension e

through a sucker it continues in its path, of which they are adjustable (fabric speed from 10 to

200 meters per minute), the thrust of the circulation pump and the rotation speed of the reel

(fig. A, 1).

The mechanical action exerted on the fabric by the overflow (0.4 Bar) is lower than that caused by the jet

(1.5 Bar) and for this reason it is preferable for dyeing very delicate fabrics.

A vacuum controlled outside the machine (fig. A, 11) unloads the pieces into a suitable tank

perforated, equipped with wheels to move the pieces to subsequent processing.

The machine is equipped with:

heat exchanger (fig. A, 6), for heating the bathroom;

circulation pump (fig. A, 7) for the overflow tank, connected to a suitable one

adjustable shutter (fig. A, 8), to establish the flow rate of the bath.

A drain valve (fig. A, 9), on the bottom of the tank, allows the residual bath to escape.

An external barrel equipped with a special drain (fig. A, 10) feeds the dye bath e

auxiliary substances.

Correct execution requires good knowledge of the machine and correct loading speed:

a speed that is too high causes thickening of the tissue and difficulty in circulating it

at the beginning of the dyeing process.

a too slow loading, can cause excessive opening of the pieces, with overlapping

of the fabric and its incorrect distribution in the sliding channel.

Wrinkles and beating if the fabric does not open in the dye channel.

Other more evident defects deriving from a machine stop in the dyeing phase, due to knots or breakages

of the fabric.

Non-uniformity of the dye.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me