© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Don't have an account yet? Register

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone: +393319020189

Working hours: 09.30 / 12.30 - 16.00 / 18.00 From Monday to Friday.

Equalization is a heat treatment, carried out on some types of both traditional and a

mesh, which evens out the height of the piece along its entire length by applying steam.

This process is usually placed at the end of the finishing cycle.

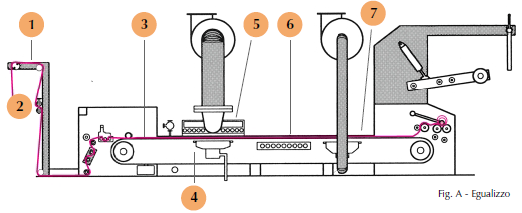

The piece, positioned in the center of the machine entrance, passes:

through a tensioner (see figure A, point 1),

in a fabric centering-stretching unit (fig. A, 2);

through a series of devices (selvedge unrolling, feelers and superchargers).

It is then dragged by two chains (fig. A, 3), equipped with plates with metal points on the

which are fixed the selvedges by the pressure of two brushes.

The first part of the machine is characterized by the presence of the articulated movement chains

to pin the patch at the height with which it appears at the beginning of the path. Chains can

be spaced from each other in such a way as to adapt them to the height of the rolling that takes place

in the second part of the machine.

The piece then passes through a steaming group, where a steaming tank (fig.

A, 4), placed under the belt, invests the fabric with its vapor, helping to make it uniform

and to equalize his height.

The fabric, heated and humidified, “relaxes”, allowing ironing in the narrower areas than

at the height set by spacing the chains.

An aspirator (fig. A, 5) removes excess steam.

Vaporized and humid, it passes into a drying field (fig. A, 6) formed by radiant batteries,

which make the fabric warm and dry when it comes out.

A cooling unit (fig. A, 7) brings the fabric to its final state, setting the height

set for the patch.

At the end of the process the piece is rolled up in large or small packs or folded in

based on the needs of the subsequent operations it will have to undergo.

The operator, acting on the control panel, must:

set the process parameters such as:

• the percentage of supercharging,

• the amount of steam,

• the transit speed of the piece.

provide the piece with the identification tag, containing the necessary data (article code,

length, weight, etc.), in the event that the piece does not have to undergo other processing and is ready

to be shipped, as it is often the last finishing process.

After the sale of the machinery we also assist you in logistics and if desired by the customer we have technicians capable of reassembling and starting the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me