© 2024 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Working hours: 09.30 / 12.30 - 16.00/18.00 From Monday to Friday.

Polyamide.

It is known by the generic name of nylon. It has good characteristics of lightness and resistance.

za. It is used in the form of multi-strand or staple wire. It is used in hosiery, for light garments

women's clothing, for raincoats and umbrellas, carpets.

Polyester (fig. 7).

Very light synthetic fibre. It can be used both in

staple and continuous burr thread. Recently

It was made in the form of microfibre.

It has high breaking strength and

good elasticity; its important characteristic is

crease-proof, wash-wear (easily washed,

dries quickly, no need to iron). Can

be used mixed with almost all fibres.

Given its good overall characteristics, it comes

used in practically all sectors (clothing, furniture and related accessories, etc.).

Polyurethane (Elastane).

Elastomeric fibre, it is produced as a continuous thread. Features: high elasticity, elongation

up to six times the initial length. It keeps its return force unchanged over time. It can be-

used pure or mixed with other unstretchable fibres, both synthetic and natural, conferring

I give them elasticity. The result is differentiated threads, depending on the manufacturing industries. Uses: tes-

elastic suits for swimwear, outerwear, sportswear, corsetry, calfs

zetteria, lace and elastic ribbons.

The characteristics of the fibers determine the greater or lesser suitability of the yarns for the creation

of a given tissue.

Depending on the chemical-physical properties of the fibers, the spinning processes are diversified in spinning

carded, combed spinning, open end spinning and extrusion spinning.

In this spinning system, virgin and/or regenerated wool fibers and other original ones are used

animal, vegetable, chemical, waste from intermediate processing of combed wool.

These are generally short cut fibres. These materials are normally used mixed with

other longer fibers which contribute to improving the technological characteristics of the yarn.

The manufacturing process includes the following phases:

to. preparation of the mixture for carding, which consists in the realization of the mixed with the various

components different in color and/or quality and quantity;

b. carding, with which the material prepared in preparation is subjected to repeated actions

mechanical techniques with the aim of loosening the fibres, parallelising them and, at the same time, blending

sea the various components, both from a qualitative-quantitative and color point of view.

Carding is made up of an assortment of three groups of machines connected to each other:

1) breaking card with automatic loader,

2) card crosspiece,

3) divider.

From the divider wicks emerge (prototypes of threads with false twist) ready to be passed to the pro-

spinning shed;

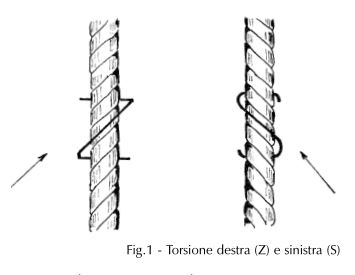

spinning, which can be carried out on spinning mills

intermittent (selfacting, fig. 2), or in

continuous (carded ring), has the purpose of tra-

unmold the yarn wicks, giving them

yes an ironing to reach the desired count

and a twist to the fibers which can be left

stra (S torsion) when the torsion propellers

they rise from right to left or right

(Z twist) when the propellers rise from the left

to the right (see figure 1). At the end of

each spire in the case of intermittent spinning

Tentatively and continuously in the case of the ring, the yarn is wound onto special tubes.

The yarns thus obtained are soft, warm and slightly hairy, suitable both for the

traditional clothing such as knitwear, particularly for the autumn/winter period.

After the sale of the machinery, we also assist you in logistics and, if desired by the customer, we have technicians capable of reassembling and starting up the machinery.

© 2024 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me