© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Orari di lavoro : 09.30 / 12.30 - 16.00/18.00 Dal Lunedi' al Venerdi'.

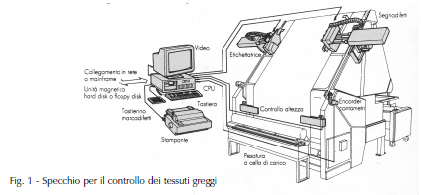

The raw fabric coming from weaving (traditional or knitted), before being subjected to

subsequent dyeing and finishing processes are checked at the client company on

special mirrors and other instruments.

The weight, height, length of the individual pieces and the number of beats are checked

centimeter. At the same time a control expert, supported by a computer (see figure 1),

detects in the mirror all possible defects resulting from upstream processing, mainly

defects on the yarns and weaving are still visually detectable, establishing the possibility and opportunity

to eliminate them before subsequent fabric processing.

The most recurring defects are the following:

1. Missing or double wefts or sections of wefts;

2. Missing or double threads or sections of threads;

3. Presence of nodes;

4. Flames or swells on the yarn;

5. Plot tangles;

6. Lateral indentations of sections of the plot;

7. Weaving bars;

8. Chiarelle (wefts not placed together) or strabattute (wefts too close together);

9. Thread threading errors;

10. Wire combing errors;

11. Missing stitches;

12. Regularity of the drawings;

13. Color error in the warp and weave note;

14. Loose wefts and threads;

15. Vertical streaks for warping defects on the courses.

If the fabric has defects exceeding the processing tolerance, the operator

communicates directly to the weaving mill the defects to be removed on the pieces still to be weaved, while for

as regards other types of defects (spinning, twisting, etc.) the employee will communicate them

to the technical office. At the end of the inspection, the piece is usually marked on the front and on the back

with the following data: the name of the manufacturer, the progressive number (serial number) of the piece, the name

or item number and the finished height. Any other data is at the discretion of the manufacturer. These

data can be imprinted on the piece using a hot-applied label or with a special marker

indelible.

Once the defects present on the raw fabric have been detected during the inspection and the various types have been established

of intervention to be carried out, the pieces are passed to the mending department, which is an operation

carried out mainly by specialized female personnel, often belonging to medical centres

mending. The employee, based on the type of fabric to be repaired and on the indication of the company to which

belongs to and of the person in charge ("master"), must carry out on the fabric, with precision and professionalism,

all those interventions, diversified based on the type of defect, essential to make it

suitable for subsequent finishing processes which may possibly be preceded

from the dry cleaners. By mending we mean all those processes that involve reconstruction

adjust the weave of the fabric, removing most of the defects indicated in the check

raw fabric and also replacing, if necessary, sections of threads or irregular wefts using

spring pliers, curved scissors and needle.

By loosening we mean all those interventions that concern the elimination of small particles from the tissue

knots and other impurities and small imperfections, which however do not influence the structure of the

fabric, using mainly spring-loaded pliers.

After the sale of the machinery, we also assist you in logistics and, if desired by the customer, we have technicians capable of reassembling and starting up the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me