© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Orari di lavoro : 09.30 / 12.30 - 16.00/18.00 Dal Lunedi' al Venerdi'.

This process can be achieved with three process methods that differ in duration

processing and the type of effects produced:

discontinuous decatizing at atmospheric pressure;

continuous decatising at atmospheric pressure;

discontinuous decatizing in autoclave.

Whatever the method, decatising substantially modifies the feel of the fabric

based on the support on which the piece is placed, called "sub-piece":

the thick, soft and hairy “mollettone” type undercloth gives a woolly and soft feel;

the "setino" type undercloth gives a shiny, rather flattened, silky and stable effect.

Process that gives the fabric a full, compact and supported feel, also giving a light

dimensional stability and allowing the elimination of any resulting excessive shine

from calendering.

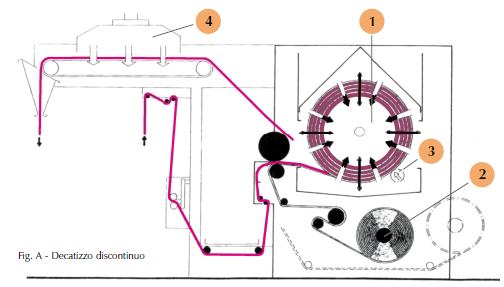

The machine is made up of two sides on which the decaterator cylinder is placed (see figure A, point 1) - in stainless steel or copper, with many small holes on its entire surface, to which tubes are applied, facing towards the inside the cylinder, which collect any condensation – and a

small cylinder on which the underpiece fabric is wrapped (fig. A, 2) for which the "setino" (compact and thin) or the "mollettone" (soft and thick due to the raising) can be used

undergone on both sides), chosen based on the type of fabric to be treated and the desired effect, considering

that a greater rigidity of the underpiece gives the fabric a more nervous, snappy and shiny feel.

The operation begins by wrapping the undercloth and the fabric to be treated together on the decat cylinder

they are held tightly adherent by an adjustable pressing roller (fig. A, 3). At the end of rolling, steam is introduced into the cylinder which, passing through the holes, hits and passes through the undercloth and fabric rolled together for as long as the operator deems appropriate. Once the flow of steam is then closed, a pump is activated which, sucking air through the holes of the decatiator cylinder,

determines the cooling of the two tissues and a more supported hand. During these two

phases (steam introduction and pump activation), the decating roller maintains a constant movement of alternating rotation, to move the fabric and facilitate the penetration of steam and air. Outside the machine there may be an air cooler (fig. A, 4) with the aim of bringing the fabric to room temperature. The machine is completed by a suction system, which eliminates the vapors that escape from the roll formed on the drum.

Finally, the treated fabric is removed while the underpiece is rewound on the appropriate cylinder.

The characteristics assumed by the tissues after this treatment will depend on

choice of underpiece fabric,

steam administration time, cooling time.

Greater steam administration time and less suction time with the pump provide

the fabric has a softer hand; the opposite treatment, however, will cause the fabric to take on a

harder hand.

The process manager must:

carefully match the fabric to be decated with the underpiece;

program and control processing times and parameters with the control panel

(steam intake, pressing cylinder pressure, steam intake).

Horizontal wrinkling of the fabric due to poor tension of the fabric and underpiece during

the winding. This defect becomes evident during the aspiration phase.

Different vertical appearance on the decatized fabric, near one of the two selvages, which

it appears untreated due to irregular wrapping at the entrance of the piece with the under-piece,

going outside of it.

The technological solutions for discontinuous autoclave decatizing are different. This card

presents the most used system in the Prato textile district, the so-called KD: machine that obtains

results and effects similar to discontinuous decatising, i.e. stronger hand, greater thickness

low, greater dimensional stabilization compared to an environmental pressure treatment,

with a greater guarantee on the eligible returns for the garment manufacturer.

It mainly deals with wool and wool blend fabrics, both carded and combed.

There are three main processing phases:

preparation of the roll of patches to be inserted into the autoclave.

In the most recent models, the preparation of the roll on the decatifier is electronically controlled,

in particular the tension of the underpiece and the centering to avoid defects in the center of the selvedge. In

older machines still carry out the rolling operation (of the fabric and the under-piece).

performed manually by the operator.

Insertion of the roll of patches into the autoclave and decatizing operation under pressure.

The roller, sliding on special guides, is introduced into the autoclave and the door is hermetically closed.

In the decating cylinder a suction system allows the steam under vacuum to flow

quickly pass through all the layers of the roll, but only when all the air is contained in the autoclave

has been expelled from this the decatising begins and the fabric is subjected to the action

of steam under pressure.

The result is determined by the processing duration and the steam pressure, parameters

these which are set from the control panel. The steam is then discharged through a

specific duct.

Extraction of the roll of patches and separation of the decated patches from the under-patch.

Once decatizing is completed, the trolley with the roll is extracted and taken towards the preparation machine

and placed in storage. In the meantime a second roll has already been prepared to be

placed in the autoclave, thus leaving room on the rails to carry the already decayed roller into the

unloading position (same place where the roll is prepared in the decating cylinder).

The underpiece is separated from the decatted fabric and wrapped on a beam, while the piece is treated

it is stacked or rolled.

In more modern machines, in addition to increasing the length of the charges, they have been

semi-automatic loading systems introduced that allow packaging to begin

of the new roll while the pieces already treated are being unloaded. Thus the machine

operates with two distinct rolls.

Depending on the models and the type of fabric to be treated, the hourly production varies from 600 to 2000 meters.

The operator's behavior when faced with the problems of this process does not differ

from what has already been said about discontinuous decatizing at atmospheric pressure.

In addition to what has been highlighted in relation to discontinuous decatizing at atmospheric pressure, this being the case

of an operation carried out at high temperatures, it is evident that any manufacturing defects

they will be more evident, deeper and more fixed.

The fabrics that undergo this treatment must have good color fastness.

The employee must:

scrupulously follow the expected process parameters;

check them on the appropriate control panel and on all control instruments (pressure gauges,

pressure gauges, drain valves, etc.) present on the machine.

After the sale of the machinery, we also assist you in logistics and, if desired by the customer, we have technicians capable of reassembling and starting up the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me