© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Working hours: 09.30 / 12.30 - 16.00/18.00 From Monday to Friday.

The Airo treatment gives both traditional and knitted fabrics, composed of natural, artificial and synthetic fibres, a fresh appearance, voluminousness and elasticity, guaranteeing a complete absence

of folds.

It can involve washing and drying the pieces or simply drying them.

The Airo machine normally performs washing, subsequent softening and drying on the rope fabric.

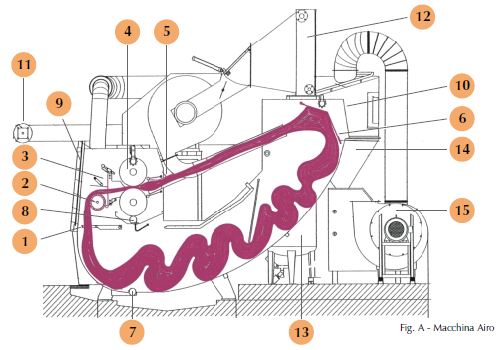

The machine is made up of a stainless steel tank inside which there are:

a rack (see figure A, point 1), where the individual pieces are inserted;

a fabric guide roller (fig. A, 2);

two cheeks (fig. A, 3);

a series of main squeeze rollers (fig. A, 4);

a stainless steel tube (fig. A, 5), which with a jet of air guides and forcefully pushes the patches;

a shaped grid (fig. A, 6), over which the fabric passes, thus causing softening

and the transformation of the look and feel of the fabric; the tank drain (fig. A, 7).

A basin and relative drain (fig. A, 8) underneath the squeezing cylinders collects and disposes of the excess water and any impurities.

For drying the fabric there are:

a heat exchanger (fig. A, 12) for heating the air

a cyclone (fig. A, 14) to remove the exhausted air

an exhaust fan (fig. A, 15).

In front of the machine, there is a fabric unloading roller (fig. A, 11) and, on the side, a tank

(fig. A, 13) for the administration of the auxiliary products necessary for processing.

The machine is completely closed but has two glass parts, one on the front (fig. A, 9) and

the other on the back (fig. A, 10).

The process must follow precise methods and parameters in relation to the type of fabric to be treated. For

for this reason the employee must:

pay extreme attention when programming the machine via the control panel;

carry out results checks both during and at the end of the cycle.

The hand and appearance must correspond to what was planned, with particular attention

to the yield possibilities of the fabric.

Since the machine can operate both as a wash and dry and dry fabric,

the operator must:

in the first case, load the appliance as for a normal wash, placing it in the tub

water and auxiliary products. After purging, it will move on to drying and subsequent extraction

of the pieces on a special pallet, paying close attention to establishing:

speed of treatment, both spring and dry;

cylinder pressure;

air temperature;

quantity of water, solvents and other products.

Collaboratively administer market research and purchasing.

New Business : +393319020189

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me