© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Working hours: 09.30 / 12.30 - 16.00/18.00 From Monday to Friday.

Vegetable raising is usually used to treat fabrics

greater value. It is carried out wet as this facilitates the extraction of the

fibres, which remain intact, resulting in less weight loss and particular shine

of woolen fabric.

For this process, vegetable thistles (see figure A) and the inflorescence are used

dry, oval in shape, elongated and covered with elastic tips and

uncinate, of a plant belonging to the dipsacaceae family.

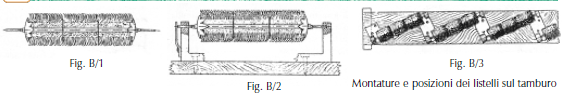

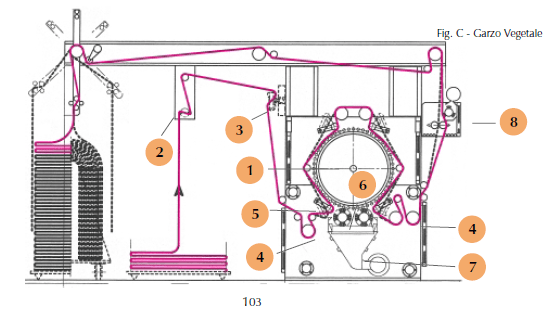

The raising machine consists of

a large drum (see figure C, point 1) of approximately 1.5 m in diameter, on which they are fixed

of the strips into which the cardoons are inserted (see figure B, point 1).

The strips, approximately 20 cm long, contain 3-4 cards depending on the length and are fixed to the drum

on a support that allows the cardoons to rotate on themselves (fig. B, 2), they are arranged inclined

with respect to the axis of the drum, to ensure that the cardoons act uniformly both on the weft and

on the warp (fig. B, 3).

The fabric passes:

through the tension cylinder (fig. C, 2) and the piece center (fig. C, 3),

it is transported by a series of rubber-coated inlet and outlet cylinders (fig. C, 4).

Its pressure on the raising drum is regulated by four dancing cylinders (fig. C, 5).

Two brushes (fig. C, 6) for cleaning the thistles are placed under the drum.

A special aspirator (fig. C, 7) eliminates the fuzz extracted from the thistles.

A brush (fig. C, 8) with relative aspirator finishes the hair on the right side, at the end of the path.

Once processing is completed, the piece is stacked or rolled on a special beam.

The effect of raising the hair and against the hair is given by the drum which can rotate in two directions, with

speed higher or lower than that of the fabric.

The intensity of the raising depends on

the pressure of the dancing cylinders on the fabric;

the condition of the thistles. The new and very elastic ones create a more intense raising.

The raiser must:

place the wet piece on the gauze;

sew the tail of the last piece with the head of the first to form the ring to be treated;

carry out constant checks on

•the state of wear of the thistles, replacing those that are out of use and removing excessive fluff;

•the effect achieved, comparing it with the reference sample.

Raising bars, deriving from an irregular garnishing of the thistles, for diversity

of diameters or different seasonings.

Uneven raising, caused by variations in fabric tension during raising.

Different hair extraction, due to irregular wetting of the fabric.

Defect clearly visible and therefore avoidable with systematic checks of the raising agent.

Streaks of fur, due to the presence of folds on the fabric.

After the sale of the machinery, we also assist you in logistics and, if desired by the customer, we have technicians capable of reassembling and starting up the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me