© 2025 All rights reserved

Project by UsedTextilemachines.eu

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

Don't have an account yet? Sign in

Do you already have an account? Go to login Click here

We are happy to assist you

Looking for the best opportunities to satisfy the customer:

Mobile Phone : +393319020189

Working hours: 09.30 / 12.30 - 16.00/18.00 From Monday to Friday.

The device called "weft straightener", which is used to keep the weft threads perpendicular to the warp threads,

It is found in the drying process in the stenter, but it is also used independently for needs

finishing and packaging.

The “straighten weft” corrects the following defects:

– the angular waste, when the weft threads are oblique with respect to the warp threads,

not always or necessarily with detectable differences between the right and left side of the fabric,

but sometimes also between both sides and the centre of the piece, with the wefts arching towards the centre;

– the sinuosity of the textures, when these, always oblique, also appear wavy.

To detect the above mentioned defects, some tests are used

optoelectronic sensors – which see electronically – particularly suitable for fabrics

knitted and for traditional fabrics that have a certain degree of transparency.

In other cases, very sensitive mechanical probes are used, adjustable in relation

to the more or less compact structure of the article being processed.

It is possible to install, especially at the end of drying, an additional mini straightener compared to

to the one supplied with the drying machine, with the aim of correcting small but significant distortions

also to report these additional small corrections to the incoming weft straightener.

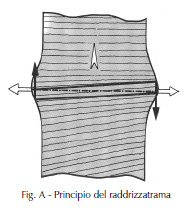

To understand the principle of straightening the wefts, let's refer to figure A, in which

the two straightening forces are observed (in black at the ends

right and left of the cloth) exerted by the cylinders.

In this

for example the plots have a slope that goes up from the left

to the right and to return them to the horizontal position, the

right side cylinder lowers and brakes the fabric while the

cylinder on the left side, rising, works as a power supply,

thus obtaining a horizontal alignment of the

plots, as can be seen in the upper part of figure A.

The signal detected by the sensors is transmitted to the device

correction, which consists of a series of straightening cylinders

rights, which have the possibility of operating diagonally, and of

curved cylinders.

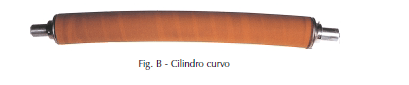

The combined action of these cylinders, set according to the interpretation of the signal, allows to

cancel distorted texture positions, by varying the dragging speeds

between one selvedge and the other. The sinuosity of the wefts is instead cancelled out by the action of the cylinders

curved (see figure B).

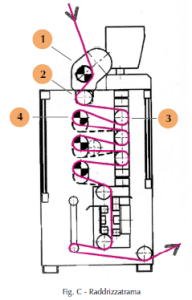

Figure C shows the path of the fabric

through the two types of cylinders.

The fabric passes:

through a tensioner (see figure C, point 1), from a conveyor cylinder (fig. C, 2), alternatively on the straight cylinders (fig. C, 3) and on the curved cylinders (fig. C, 4). The curved cylinders (fig. C, 4) can assume:

concave position when the wefts are convex with respect to the selvedges,

convex position when the textures are concave.

The straight cylinders (fig. C, 3) can be moved laterally, forwards or backwards relative to the fabric, exerting forces on the fabric as indicated in figure A.

Another system of straightening the weft is used when a diagonal waste occurs

from selvedge to selvedge and exploits the state of tension that is created in the crooked wefts.

the cloth is anchored at both ends to two disks decorated with needles. The disks (drums) are not

controlled but free to turn in the direction of the fabric's advancement, while their mutual position is offset along an oblique line if the weft is crooked. This creates tension on the weft itself and the composition of the forces causes a realignment of the end that is lagging behind.

After the sale of the machinery, we also assist you in logistics and, if desired by the customer, we have technicians capable of reassembling and starting up the machinery.

© 2025 All rights reserved

Project by UsedTextilemachines.eu

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Analytics" category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by the GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the "Performance" category. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out the form to contact me